Innovative backflush technology for maximum efficiency in coolant filtration

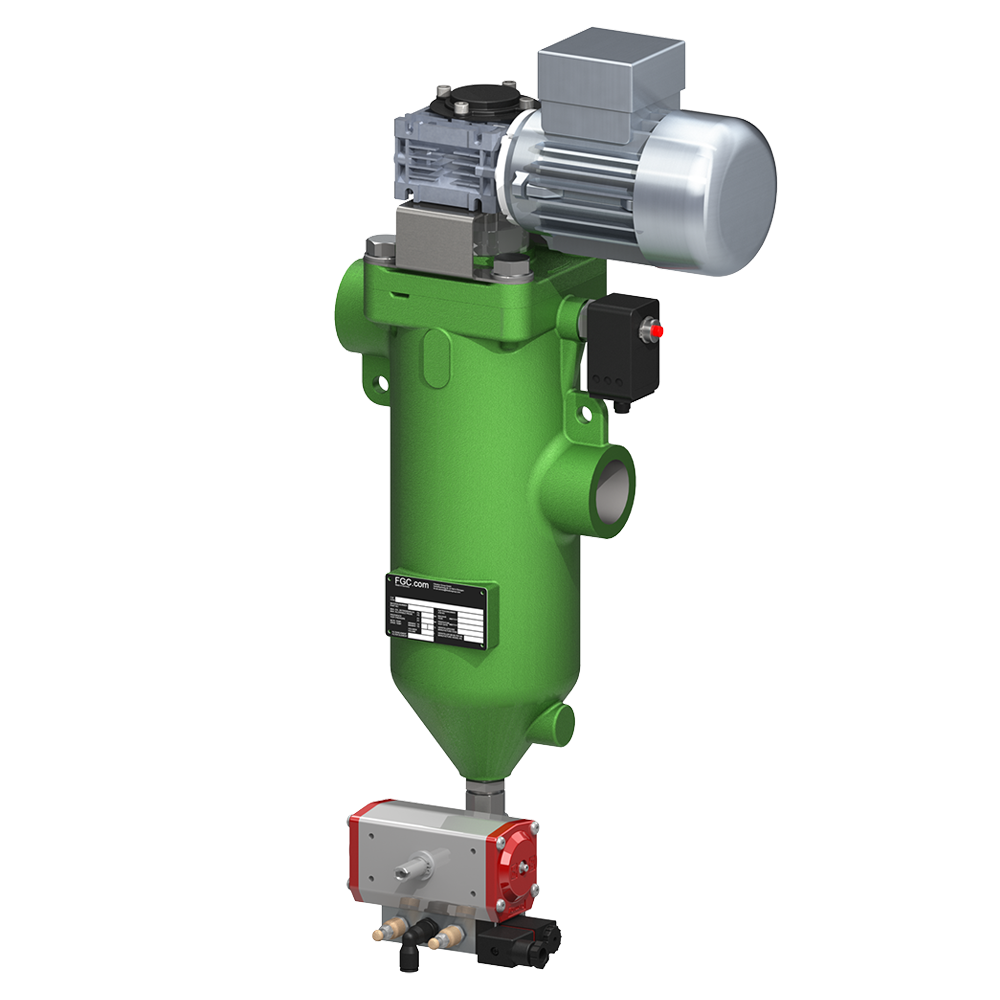

With the AF 122 automatic backflush filter, Filtration Group Industrial presents a modern, compact, and highly efficient filtration solution specifically designed for applications with water-miscible and non-water-miscible coolants. The fully automatic filtration system impresses with its sophisticated design, segmented high-performance cleaning, and flexible adaptability to specific on-site conditions.

Why is the AF 122 so impressive?

The demands placed on filtration solutions are constantly increasing – both in terms of quality and cost-effectiveness. The AF 122 meets these expectations with flying colors. Our customers therefore benefit from:

- Application-oriented filter series

- Compact design

- Reliable performance up to a dirt load of 200 mg/l

- Minimal maintenance thanks to reduced component count and consistent use of identical parts

- Very low life-cycle costs, as no filter media is consumed

- Highly efficient cleaning through segmented filter elements and a powerful backwash pulse – without interrupting filtration

These advantages make the AF 122 from Filtration Group a powerful and future-proof "cleaner" for higher flow rates.

Ecologically and economically compelling

One central goal was paramount in the development of the new series:

To create a filter system that saves costs in the long term without compromising filtration quality!

The AF 122 delivers precisely that:

- Extended service life of tools, pumps, machines, and systems

- Reduced maintenance

- No consumables

- Sustainable filtration through high energy efficiency

These factors lead to a noticeable return on investment in the medium term. Companies thus benefit twice over – economically and ecologically. And last but not least, reliable filtration increases process reliability and, consequently, overall plant operation.

Operating principle: Efficient, uninterrupted filtration

The AF 122 operates on the principle of surface filtration. The medium is introduced into the filter housing at a pressure of over 2.5 bar and flows from the inside out through the segmented element. Particles are deposited on the surface, while the purified medium exits the housing opposite the inlet.

Automatic Segment Cleaning

The cleaning process starts:

- when a preset differential pressure is reached or

- at predetermined intervals.

While the cleaning valve is open, the backwash channel inside the element rotates. The segments are opened and sealed sequentially – particles are effectively removed from the filter surface by the impulse and discharged with a minimal amount of fluid.

Just one rotation is sufficient to completely clean all segments.

Increased Performance with the Wave Element

The AF 122 can optionally be equipped with the innovative Wave Element AF 120174-XXX from Filtration Group.

The pleated surface enables:

- significantly larger filtration area

- almost twice the flow rate compared to standard elements

CONCLUSION: Simple, automatic, and economical filtration

The new AF 122 backwash filter meets the highest demands in industrial filtration – reliably, efficiently, and sustainably. Companies that value process reliability, low operating costs, and robust, future-proof technology will find a high-performance solution in the AF 122.

Flyer FG Automatic Backwash Filter AF 122

By the way: In the FILCOM online shop, you will find a wide selection of automatic filter elements for a variety of applications and filter types.

Whether for existing systems or for individual requirements – our product range offers high-quality replacement and accessory components that are optimally suited to a wide variety of filtration processes. Feel free to browse our shop!

Do you also need a reliable filter for high flow rates?

Dann sprechen Sie uns an - das Team der FILCOM GmbH berät Sie gerne persönlich!

Carmen Steiner

Marketing & Sales

- info@filcom.de

- +49 711 / 441 33 22 - 36