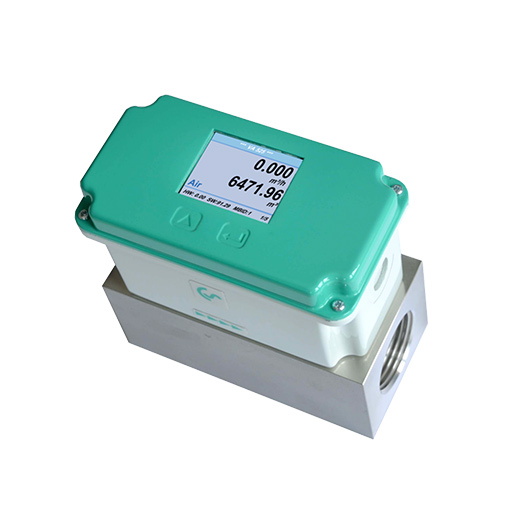

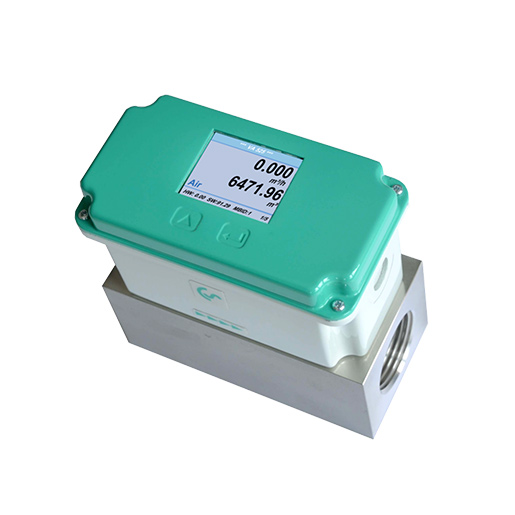

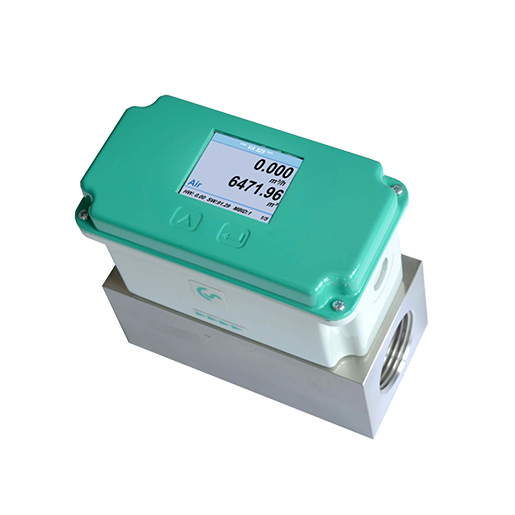

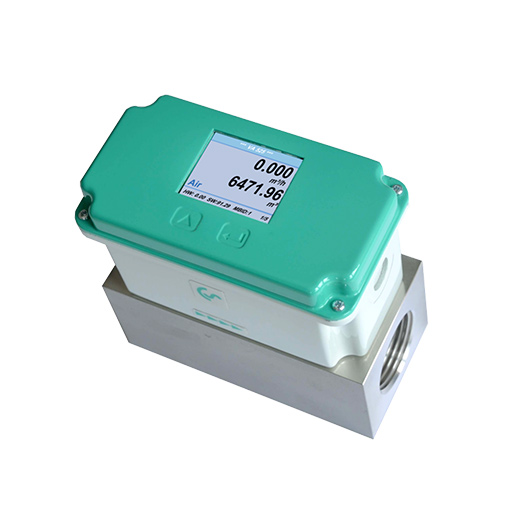

CS Instruments VA 525 Compact inline flow sensor G 1 1/2"

Measuring range end value: 730 m³/h

The newly developed VA 525 with measuring block G 1 1/2" includes modern digital interfaces for connection to flow monitoring systems in a small and compact design.

CS Instruments

As a leading manufacturer of compressed air measurement technology, CS INSTRUMENTS stands for highest quality and innovation. "Made in Germany" is our practice - development, production, and calibration take place exclusively in Germany.

VA 525 G 1 1/2" - Compact sensor for precise measurement of compressed air and nitrogen

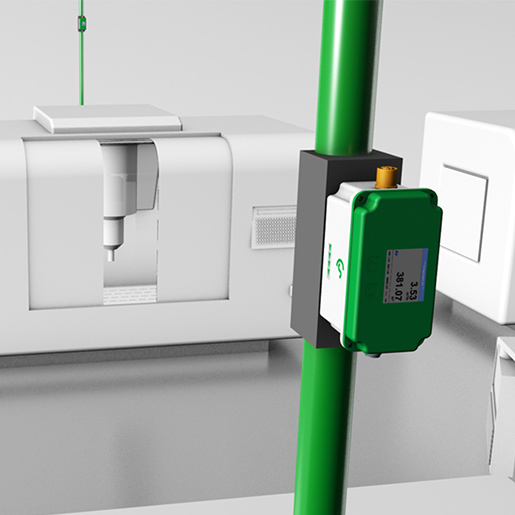

The newly developed VA 525 compact sensor combines modern digital interfaces for optimum connection to energy monitoring systems with a compact design. It is used in particular when several compressed air consumers need to be integrated into an energy monitoring network.

Reduce your energy costs and increase the sustainability of your company with the VA 525. Monitor the consumption of individual machines and analyze leaks with just one powerful measuring device.

Advantages of the compact VA 525 flow sensor:

- Precise measurement of the mass flow rate: The VA 525 provides a direct output of the standard volume flow rate without the need for additional measurements of pressure and temperature.

- Compact design: The device is ideal for installation in confined spaces and requires no inlet and outlet sections thanks to the integrated flow straightener.

- Optional pressure sensor: The VA 525 is also available with an integrated pressure sensor.

- Highly accurate: It delivers precise measured values at both low and high flow rates.

- Low maintenance: As there are no moving parts, the sensor is particularly easy to maintain.

- Versatile use: The VA 525 is suitable for both compressed air and nitrogen.

Technical details of the VA 525:

- Serial interfaces: 04...20 mA and pulse as well as Modbus RTU (RS 485).

- Optional interfaces: Modbus TCP (Ethernet), PoE, M-Bus are also available.

- Pressure range: Up to 16 bar.

- Temperature range: Up to 60 °C.

- Integrated display: Clearly shows the measured values.

- Available sizes: Available in sizes from 1/4" to 2".

- User-friendly settings: Adjustments can be made directly via the buttons on the display.

- Restoring the main counter reading: Can be reset via the display.

- Machining speed: Suitable for speeds up to 224 Nm/s.

- High accuracy: With an accuracy of ±1.5% or ±1% of the measured value and ±0.3% of the final value.

Use the VA 525 to monitor your compressed air and nitrogen systems more effectively and optimize your operating costs with precise measurements and innovative technologies.

| Measured variables | m³/h, l/min (1000 mbar, 20 °C) for compressed air or Nm³/h, Nl/min (1013 mbar, 0 °C) for gases |

| Measuring range | 730 m³/h |

| Units via keypad on the display | m³/h, m³/min, l/min, l/s, ft/min, cfm, m/s, kg/h, kg/min, g/s, lb/min, lb/h |

| Sensor | Thermal mass flow sensor |

| Measuring medium | Air |

| Accuracy (v. M. = from measured value) (v. E. |

± 1.5 % of the average ± 0.3 % of the average on request: ± 1 % of the average ± 0.3 % of the average |

| Operating pressure (bar) | up to 16 |

| Digital output | RS 485 interface (Modbus-RTU), optional: Ethernet interface PoE, M-Bus |

| Druckmessung | 0...16 bar, accuracy: 1%, or 10...2000 mbar (abs) |

| Operating temperature | -20...60 °C |

| Analogue output | 4...20 mA for m³/h or l/min |

| Pulse output | 1 pulse per m³ or per liter galvanically isolated. Pulse value can be set on the display. Alternatively, the pulse output can be used as an alarm relay |

| Supply | 18...36 VDC, 5 W |

| Burden | < 500 Ω |

| Housing | Polycarbonate (IP 65) |

| Messblock | Aluminum |

| Anschlussgewinder der Messblöcke | G 1 1/2" |

| Installation position | any |