Innovative compressed air technologies for greater efficiency and sustainability

The manufacturing industry is undergoing profound change. Digitalization, automation, and the demand for sustainable production are rapidly transforming processes and requirements. A reliable, energy-efficient, and future-proof compressed air supply forms the backbone of modern production facilities. This is precisely where KAESER Compressors comes in – with innovative solutions that combine efficiency, availability, and sustainability.

Efficiency that sets standards: ASD and Aircenter series screw compressors

In particular, the KAESER ASD series screw compressors and the compact Aircenter systems represent intelligent compressed air technology with optimal energy and space management.

ASD Series – Industrial Performance for demanding applications

The ASD screw compressors cover a broad performance range and offer powerful compressed air output with high energy efficiency. The models are available in various motor outputs and can be adapted to the specific requirements of manufacturing plants.

- Motor outputs from approximately 18.5 kW to over 30 kW

- Flow rates from approximately 3.16 m³/min to over 5.5 m³/min – depending on the operating pressure

- Operating pressures ranging from 7.5 bar to over 13 bar. Thanks to the Sigma profile and modern controls, these compressors offer significant energy savings compared to conventional systems.

Schraubenkompressoren Serie ASD.pdf

HerunterladenRotary Screw Compressors ASD-Series.pdf

HerunterladenAircenter – Integrated Complete Systems for Efficiency and Space Savings

The Aircenter series combines a screw compressor, compressed air receiver, and refrigerant dryer in a compact, ready-to-use system – ideal for small to medium-sized production facilities.

Key specifications of the Aircenter models:

- Airflow rates from approximately 0.26 m³/min to approximately 2.7 m³/min, depending on the model

- Selectable operating pressures: 8 bar, 11 bar, or 15 bar

- Motor outputs typically range from 2.2 kW to 15 kW. Aircenter systems are plug-and-work capable and require only electricity and a compressed air connection for immediate on-site use.

Schraubenkompressoren Serie SK.pdf

HerunterladenSchraubenkompressoren Serie SM.pdf

HerunterladenSchraubenkompressoren Serie SX.pdf

HerunterladenRotary Screw Compressors SK-Series.pdf

HerunterladenRotary Screw Compressors SX - HSD Series.pdf

HerunterladenHeat Recovery: Utilizing Energy Instead of Wasting It

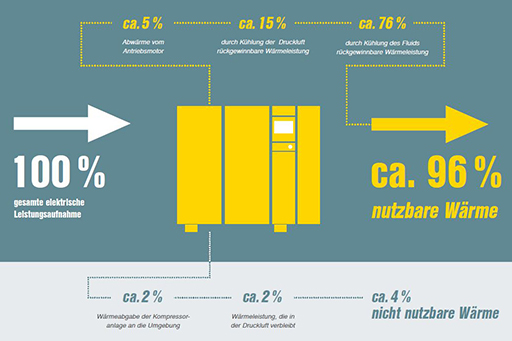

A particularly effective lever for increasing efficiency is the systematic utilization of waste heat from screw compressors. Modern fluid-cooled compressors convert nearly 100% of the electrical energy used into heat – and up to 96% of this can be used for energy recovery. This usable heat can be used for heating, hot water preparation, or industrial process heat.

Advantages of heat recovery:

- Significant reduction in energy costs: Energy costs often account for up to 80% of a compressor's life cycle costs – heat recovery allows for a sustainable reduction in these costs.

- CO2 reduction: More efficient energy use simultaneously means lower CO2 emissions.

- Flexible use: Warm air can be used for hall or process heating and hot water preparation at temperatures up to approximately 70°C, with up to 76% of the energy recoverable.

Heat recovery systems can be directly integrated into new compressor systems or retrofitted – for customized, cost-effective energy optimization.

Clean and dry compressed air: Secotec refrigerated dryers

Only optimally treated compressed air guarantees precise manufacturing results. KAESER's Secotec refrigerated dryers stand for energy-efficient, reliable, and economical compressed air drying.

Features and benefits:

- Wide performance range: Secotec models cover industrial requirements from small units (e.g., 0.6–3.9 m³/min) to larger dryers for over 34 m³/min – depending on the series (TA to TF).

- Energy-saving control: Thanks to intelligent storage control and the innovative SECOPACK LS heat exchanger system, excess cooling capacity can be stored in the thermal storage tank and used later without additional energy – this significantly reduces energy consumption and ensures stable pressure dew points.

- Stable pressure dew points: The large thermal storage mass enables stable pressure dew points even under partial load or fluctuations in operation – essential for high-quality compressed air.

- Robust construction: Corrosion-resistant air piping, an aluminum heat exchanger, and the Sigma Control Smart electronic control system ensure a long service life and ease of use.

- Industry 4.0 integration: With the optional Modbus TCP communication module, Secotec dryers can be fully integrated into the SIGMA NETWORK and centrally monitored and controlled via the Sigma Air Manager 4.0.

All energy-saving SECOTEC refrigerated dryers in the shop

Efficient and robust: i.Comp and EPC series piston compressors

KAESER also offers high-performance, durable piston compressor systems – perfectly suited to tradespeople, workshops, and small industrial operations.

i.Comp – oil-free, speed-controlled, and easy to maintain

The i.Comp series comprises oil-free piston compressors with speed-controlled drives that operate efficiently even under partial load and deliver precise compressed air.

- Flow rates from approximately 404 l/min to 570 l/min at operating pressures up to 11 bar

- Motor power from 3.1 kW to 4.2 kW

- Very low sound pressure levels of less than 66 dB(A) – ideal for workshop use

- Variable speed control saves energy and reduces mechanical wear

Thanks to oil-free and therefore emission-free compression, i.Comp compressors are particularly suitable where pure compressed air is required.

EPC - Robust Piston Compressors for Workshop and Industry

The EPC series comprises stationary piston compressors with a large, slow-speed compressor unit:

- Intake volume from approximately 112 l/min to over 1000 l/min, depending on the model

- Maximum pressures up to 10 bar or 15 bar - suitable for many typical workshop applications

- Robust construction with double vibration isolation for quiet continuous operation

- Flexible installation options - horizontal, vertical, or with a separately mounted tank

The EPC series is ideal for users who need cost-effective, reliable compressed air for classic workshop and production tasks.

All EPC piston compressors in the shop

Compressed Air 4.0: Sigma Air Manager 4.0 - Intelligent Management for Maximum Efficiency

With the Sigma Air Manager 4.0 (SAM 4.0), KAESER takes compressed air management to a new level. This demand-driven, networked system controls and monitors the entire compressed air station - including compressors, dryers and filters - for maximum energy efficiency and operational reliability.

Features and Benefits of Sigma Air Manager 4.0:

- Demand-driven control: Adjusts compressor output according to current compressed air consumption – reducing unnecessary energy consumption.

- Centralized networking: All components of the compressed air station are linked in real time via the Sigma Network, enabling comprehensive monitoring and intelligent energy management.

- Comprehensive monitoring: Operating parameters, alarms, and maintenance information are systematically recorded and displayed – reducing downtime and allowing for proactive maintenance planning.

- Industry 4.0-ready: Thanks to open communication interfaces, additional components such as Secotec dryers can be integrated, enabling complete digital control of the compressed air station.

Sigma Air Manager.pdf

HerunterladenCompressed Air Management System Sigmar Air Manager 4.0.pdf

Herunterladen

CONCLUSION: Sustainable compressed air – technically powerful and expertly supported.

Modern manufacturing facilities today need more than just high-performance compressors: They require holistic compressed air solutions that intelligently combine energy efficiency, operational reliability, and sustainability. KAESER Kompressoren offers a comprehensive portfolio for this purpose - from highly efficient screw and piston compressors to intelligent heat recovery and networked compressed air management with the Sigma Air Manager 4.0

607 As a certified partner of KAESER compressors, FILCOM supports companies throughout the entire lifecycle of their compressed air systems. With expert consultation, professional planning, skilled installation, and reliable service and maintenance, our team ensures that every compressed air solution is optimally tailored to individual requirements. This results in cost-effective, future-proof compressed air concepts that save energy, secure processes, and sustainably strengthen competitiveness.

Kontaktieren Sie jetzt unser Team und lassen Sie sich unverbindlich beraten.

NICK BENDER

Technical advice & sales

- druckluft@filcom.de

- +49 711 441 33 22-0

WILFRIED LEITENBERGER

Managing Director FILCOM GmbH

- w.leitenberger@filcom.de

- +49 711 441 33 22 - 51