Pi 203 and Pi 204 – High-performance cleaners for mobile and stationary hydraulic applications

In modern hydraulic systems, the cleanliness of the hydraulic fluid is crucial for reliability and service life. The new Pi 203 and Pi 204 inline filter series from Filtration Group Industrial offers innovative solutions for mobile and stationary applications with high filtration performance and durable technology.

Pi 203 – Compact inline filter for dynamic scenarios

The Pi 203 is specifically designed for mobile hydraulic applications. Its advantages:

- Flow rate range: 40 to 110 liters per minute

- Weight: extremely lightweight – the lightest model weighs less than 1 kg

- Operating pressure: up to 100 bar, with a fatigue strength of 5 x 10⁵ load cycles in the 0–100 bar range

- Temperature range: -10°C to +120°C (other ranges available upon request)

- Materials: Aluminum filter head and housing, NBR (nitrile rubber) seals

- Bypass opening pressure: Δp 3.5 bar ±10% ensures reliable flow even with a clogged filter element

The compact and lightweight design allows for easy integration into moving hydraulic systems, where space and weight are often critical factors.

Pi 204 - Robust Pressure Filter for Stationary Applications

The Pi 204 is designed to meet the highest demands in stationary hydraulic systems and is characterized by:

- Flow rate: 40 to 110 liters per minute

- Operating pressure: up to 250 bar, fatigue strength 10⁶ load cycles at 0–250 bar

- Test pressure: 360 bar for maximum safety

- Materials: robust filter head made of spheroidal graphite cast iron (GGG), steel housing, seals also made of NBR

- Temperature range: -10 °C to +120 °C

- Bypass opening pressure: Δp 7.0 bar ±10%, ensuring a reliable fluid flow even at elevated pressures

The robust design ensures maximum reliability even under extreme operating conditions and harsh environments.

Shared technical highlights

Both filter series are designed for in-line installation and feature:

- Sizes and Connections: Threaded connections and modular systems for optimal adaptation to a wide variety of systems

- Filter Elements: High-performance PulseShield™ filter elements with patented pleated star mounting for consistently high separation efficiency

- Maintenance Indicators: Optical, electrical, or electronic versions with IP 65 protection for safe and reliable operational monitoring

- Maintenance Indicator Switching Points: Pi 203 at Δp 2.2 bar ±10%, Pi 204 at Δp 5.0 bar ±10%

- Electrical Data: Maximum 250 V AC/200 V DC, switching current max. 1 A, switching power 70 W

- Temperature and Pressure Resistance: Suitable for a wide range of industrial hydraulic applications

- Multipass Test according to ISO 16889: Guaranteed and certified separation rates that demonstrate the quality of the filter performance

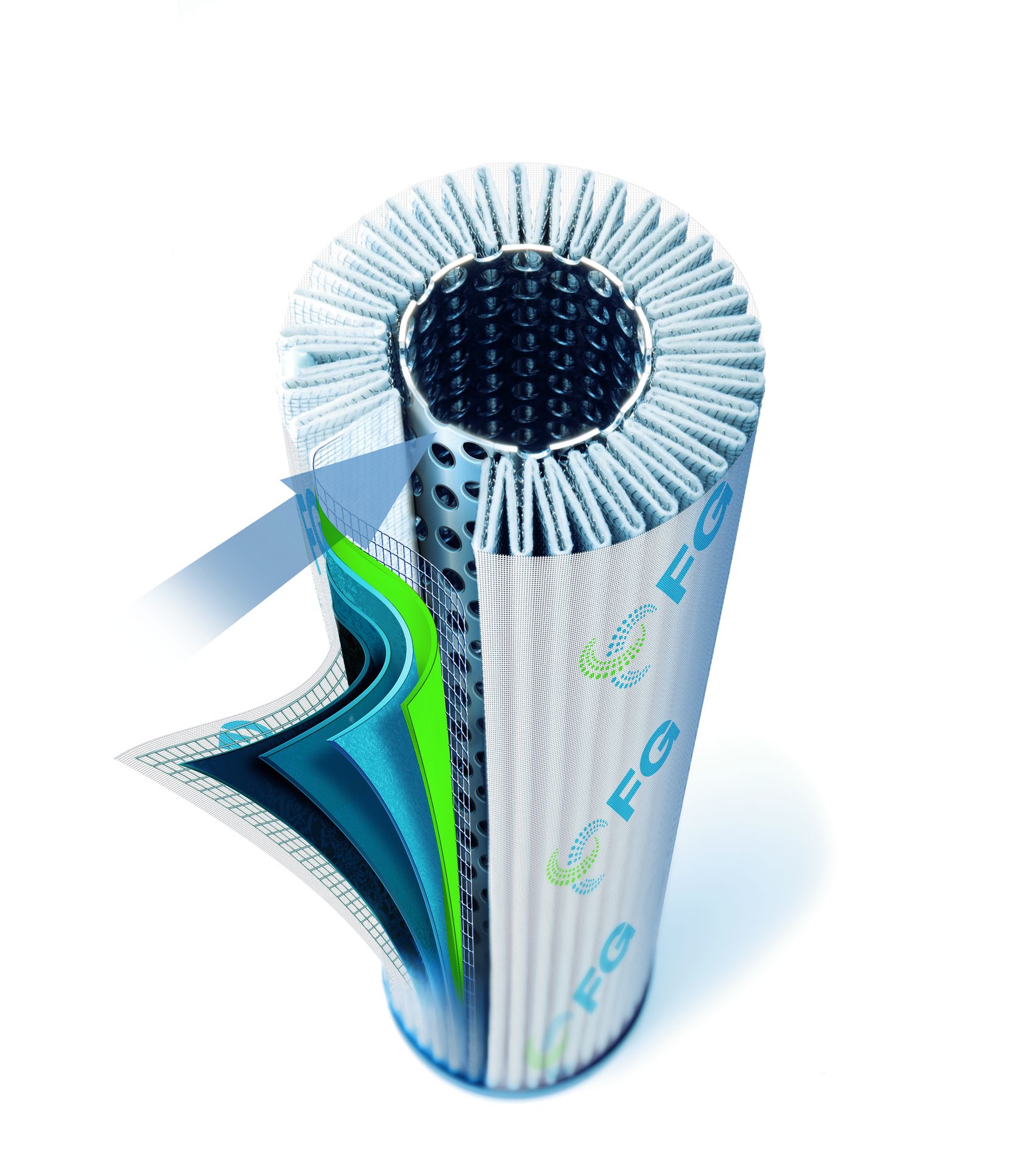

PulseShield™ Technology – Innovation for lasting filter performance

A key component of the filter series is the patented PulseShield™ technology. This ensures that the pleats of the filter element are mechanically fixed by pressing the shrunk-on outer shell against the inner frame. This prevents the pleats from clumping and ensures that the entire filter surface remains consistently available throughout the filter's lifespan.

Technical advantages in detail:

- Maximum filter area: No pleat blockages allow for full utilization of the installed filter area.

- Consistently high separation efficiency: Throughout the entire service life of the filter elements.

- Reduced pressure loss: Optimized flow characteristics increase the energy efficiency of the system.

- Patented design: Unique technical solution for reliable and long-lasting filter performance.

Maintenance and operation – Easy handling guaranteed.

Maintenance is quick and easy:

- Shut down the system and relieve the pressure on the filter side.

- Open the filter housing by turning it counterclockwise.

- Remove the filter element, check the seals for damage, and replace them if necessary.

- Insert a new, original replacement filter element (the plastic sleeve serves as protection during installation).

- Mount the filter housing with the threads lightly oiled (maximum tightening torque Pi 203: 30 Nm; Pi 204: 60 Nm).

The filter elements are designed as disposable products and should be replaced when the maximum differential pressure is reached. Maintenance indicators provide visual and electrical signals to assist with this.

Flyer Inline-Filter Pi 203-204

CONCLUSION

The Pi 203 and Pi 204 inline filters from Filtration Group Industrial offer powerful solutions for every hydraulic application thanks to their technical sophistication and innovative PulseShield™ technology. Whether in lightweight mobile applications or stationary systems with the highest pressure requirements, these filters ensure consistently reliable hydraulic fluid cleanliness and effectively protect your systems from wear and tear and failure.

Interested?

Das Team der FILCOM GmbH steht Ihnen gerne beratend zur Seite und liefert maßgeschneiderte Lösungen für Ihre Hydraulikanwendungen. Kontaktieren Sie uns und profitieren Sie von den Vorteilen der neuen Inline-Filterbaureihe.

Carmen Steiner

Marketing & Sales

- info@filcom.de

- +49 711 / 441 33 22 - 0