Surface Technology

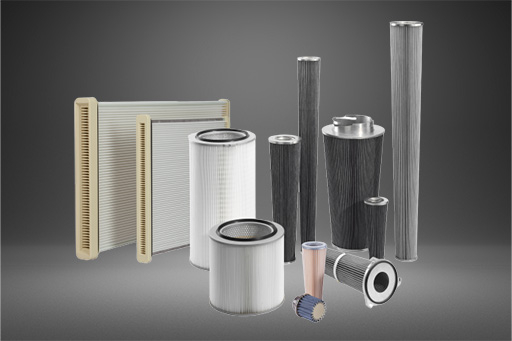

Filtration plays a central role in surface technology: it reliably separates chips, dust, and contaminants from air and media, thus creating the foundation for safe, clean, and economical production processes. Whether for dust extraction in machining centers, coating and blasting systems, or the filtration of cooling lubricants, high-performance filter systems protect people, machines, and products alike.

The targeted use of modern filtration reduces machine wear, extends the service life of tools and filter elements, and ensures consistently high surface quality. At the same time, maintenance, downtime, and operating costs are reduced. Clean media and pure process air increase process stability, improve working conditions, and ensure reproducible results—even under high dust loads and demanding applications.

The result: increased productivity, reduced resource consumption, and sustainable quality assurance along the entire process chain.

Industry in focus

Filtration: the key to stable processes and perfect surfaces

Industry applications

Filtration for safe processes in surface technology

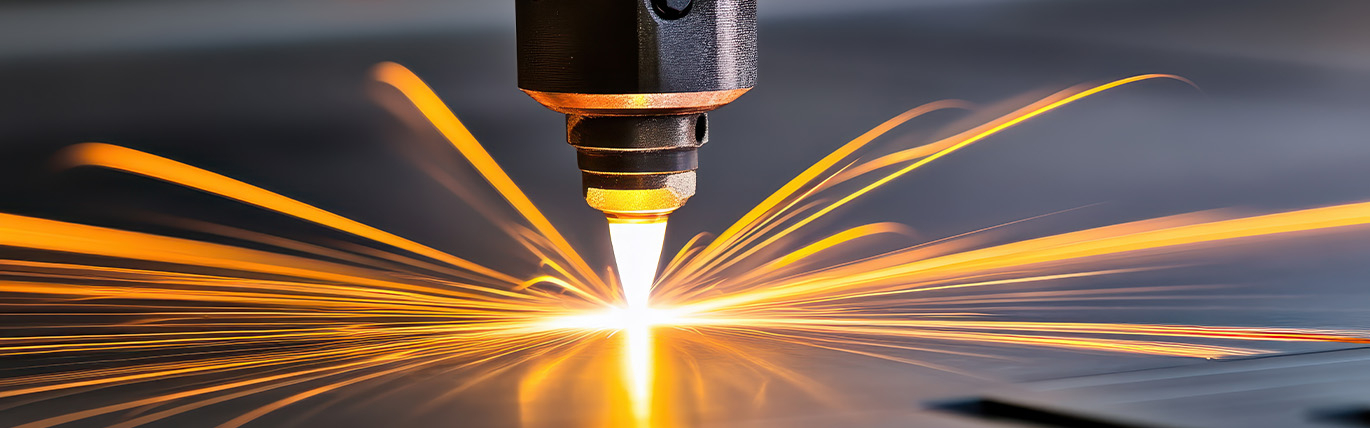

Chip and fine dust separation

In surface finishing, the machining of gray cast iron, free-cutting steels, and brass inevitably produces short chips and high levels of fine dust. Without reliable filtration, these emissions lead to increased machine stress, accelerated wear, and a compromised working environment. High-performance filter elements play a crucial role here: They ensure clean process air, stable production conditions, and consistently high surface quality.

Dust collection systems from Filtration Group effectively separate coarse chips right at the inlet. This significantly reduces dust exposure in machines and the surrounding environment, and sustainably relieves the strain on the filter elements. A flow-optimized design guarantees maximum service life and consistently high separation efficiency – even in demanding applications with high dust loads.

Dust filter elements from Filtration Group offer maximum filter surface area in the smallest possible installation space. This is made possible by the innovative pleat spacing using Pleat-Lock or cam technology, which prevents the pleats from sticking together and ensures effective use of the entire filter. In combination with coordinated cleaning systems, reliable and gentle cleaning is ensured even at high differential pressures.

The result: reduced maintenance intervals, lower operating costs, longer filter lifespans, and consistently safe and clean production in surface finishing.

Related products

- Cleaning systems

Filtration in powder coating and finishing systems

Dust collection systems from Filtration Group are used worldwide in surface finishing, powder coating, and blasting systems, reliably proving their worth in demanding applications. Whether flame spraying, grinding, polishing, or wet paint overspray extraction in large paint lines, Filtration Group filter systems efficiently remove even high dust loads, ensuring clean process air and a healthy working environment.

At the heart of these systems are high-performance filter media made of cellulose, polyester, or polypropylene, equipped with special finishes. This combination guarantees high filter efficiency and maximum service life, even under extreme conditions. The dust collection units thus ensure continuous dust separation, reduce cleaning efforts, and make a significant contribution to process stability and product quality.

Related products

- Dust collection units

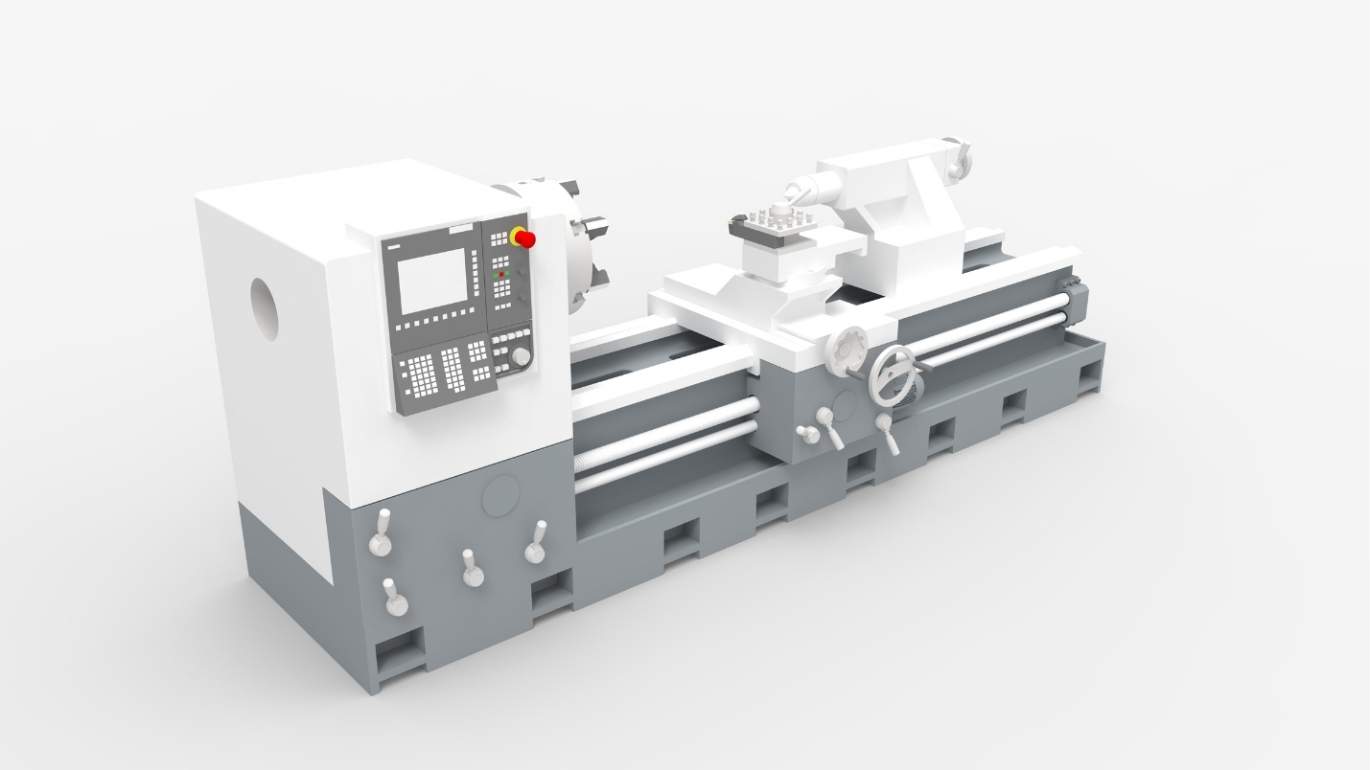

Cooling lubricant filtration

In the metalworking industry, cutting emulsions, grinding oils, and cooling lubricants play a central role in ensuring smooth and efficient production processes. The careful filtration of these media minimizes wear on expensive precision machinery, protects sensitive components, and significantly contributes to the surface quality of manufactured products.

Filtration Group's customized filter systems and modular filter solutions offer the right technology for every application: Robust strainers reliably remove coarse contaminants, thus protecting subsequent process stages. Automatic backflushing filters ensure the highest standards of purity and efficiency, filtering even the finest particles from cooling lubricants – ideal for machining processes with internal coolant supply.

These systems not only guarantee consistently high media quality but also extend the service life of tools and machines. This leads to less downtime, reduced maintenance costs, and a noticeable increase in production output. In this way, metalworking companies are supported in sustainably maintaining their high product and production standards and achieving economic success.

Related products

- Automatic backflushing filters

- Strainers

Our brands

Strong partners for surface technology

Filtration Group GmbH

Filtration Group develops and supplies high-performance filtration products for cleaning cutting emulsions, grinding oils, and cooling lubricants in the metalworking industry. Clean process media are the foundation for stable production processes, reduced machine wear, and consistently high surface quality.

The product range extends from robust strainer basket filters for the reliable removal of coarse particles to automatic backflushing filters for continuous fine filtration – even in demanding machining processes with internal coolant supply. All filter systems are designed for high flow rates, long service life, and low-maintenance continuous operation.

With its filtration solutions, Filtration Group reduces wear, lowers operating costs, and ensures reproducible production quality – for efficient, economical, and future-proof metalworking.

Go to brand pageNews from the world of filtration

Learn about innovations, tips, and industry trends

Knowledge that moves you forward

In our blog about surface technology, we share in-depth expertise, practical insights, and the latest developments in filtration and process optimization. Whether it's dust removal, media filtration, or clean production conditions, our articles demonstrate how modern technologies contribute to ensuring surface quality, maintaining stable processes, and sustainably raising production standards.

Learn more about industry-specific applications, innovative filtration solutions, and proven best practices. Our experts illuminate the technical background, explain the interrelationships, and provide concrete suggestions on how to specifically improve efficiency, cost-effectiveness, and operational reliability in surface technology.

Downloads

All documents at a glance

FG Automatikfilter.pdf

HerunterladenFG Hydraulikfilter.pdf

HerunterladenFG Lufreinhaltung.pdf

HerunterladenFG Automatic filters.pdf

DownloadFG Hydraulic filters.pdf

DownloadFG Dust filtration.pdf

DownloadYour direct line to FILCOM

Consulting and service for all your filtration technology needs, tailored to your specific requirements.