Wind energy

Whether on land or at sea, technical systems in the energy and industrial sectors must operate reliably even under the harshest environmental conditions. Wind, humidity, saltwater, high temperatures, and mechanical stresses place the highest demands on all systems used. High-performance filtration is therefore a crucial factor for operational reliability, efficiency, and longevity.

FILCOM, together with Filtration Group Industrial, offers a comprehensive portfolio of filtration solutions for demanding applications in wind turbines, service and transformer platforms, and other key industrial sectors. Our solutions reliably protect hydraulic and lubricating media, air, and process fluids from contaminants, thus significantly contributing to the reduction of wear, downtime, and maintenance costs.

Through continuous development, high quality standards, and flexible design, our filtration systems ensure sustainable and economical plant operation—even under extreme conditions.

Industry in focus

Reliable filtration for extreme operating conditions

Industry applications

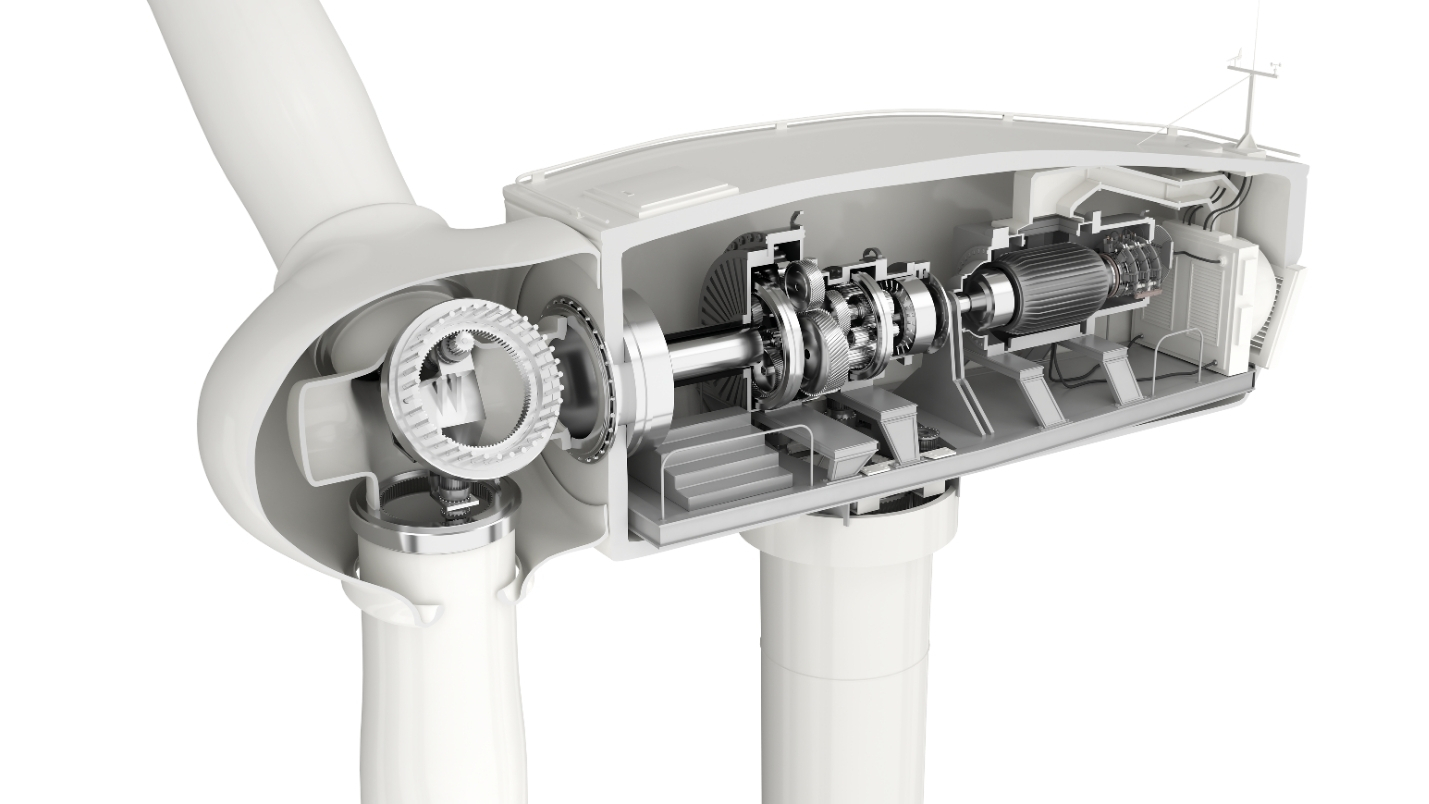

Stronger in the wind - filtration for every key component

Oil filtration in the Pitch System

A precisely functioning pitch system is crucial for the efficient and long-lasting operation of a wind turbine. The exact adjustment of the rotor blades requires a reliably functioning hydraulic system. Filtration solutions from Filtration Group ensure consistently clean hydraulic fluids and effectively protect the system from contaminants that could impair performance and operational safety.

Related products

Oil filtraton in the braking system

To guarantee optimal performance and maximum safety at all times, even in strong winds, precise control of the turbine's operating speed is essential. The braking system plays a central role in this, as it enables rapid and reliable shutdown, thus preventing mechanical damage. The purity of the operating fluids is a prerequisite for the flawless operation of the brake and hydraulic components. Filtration solutions from Filtration Group ensure that brake and hydraulic fluids remain clean at all times. This increases operational safety, prevents malfunctions, and extends the service life of the components.

Related products

Filtration for Service and Transformer Platforms

Surface water accumulates on service and transformer platforms during operation, for example, from rain or sea spray. This water is collected in specially designed drip trays beneath the transformers to prevent environmental contamination. Since the collected water is often contaminated with process oils and other impurities, it must be thoroughly purified before being discharged into the sea. Filtration Group offers a comprehensive and high-performance range of filtration and purification systems that meet all relevant environmental and safety regulations. Our solutions thus ensure not only the protection of sensitive environmental areas but also the smooth and sustainable operation of the platforms.

Related products

- Deoiler

- Fuel treatment plants

- Sea water filters

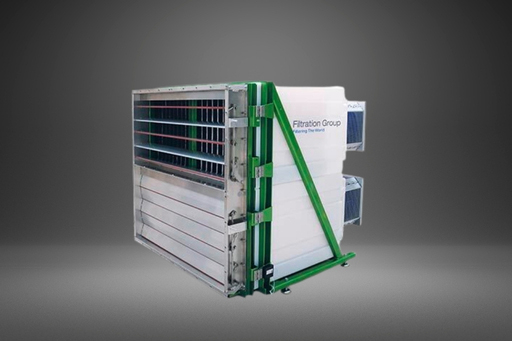

Filtration for Tower Air Conditioning

Inside the towers of wind turbines are all the control and electronic systems essential for the safe and efficient operation of the turbines. During operation, high temperatures are generated, necessitating reliable cooling of the tower environment to protect sensitive components from overheating and ensure optimal performance. Especially when cooling with ambient air, it is crucial to dehumidify the air before it enters the tower, as moisture can lead to corrosion and long-term damage to the electronic systems. Filtration Group offers specially developed air conditioning systems tailored to the requirements of onshore and offshore wind turbines. These systems ensure efficient dehumidification and cooling, protect the sensitive electronics, and thus significantly increase the operational reliability and lifespan of the turbines.

Related products

- Tower Conditioning Unit (TCU)

Gear oil filtration

For reliable and efficient maintenance of gearbox oil – in both main and bypass systems – Filtration Group offers a compact and powerful oil filter module. This module can be flexibly combined with oil coolers from the Filtration Group product range to ensure optimal cooling and filtration. This integrated filter-cooler-pump unit, as a complete system, maintains consistently high oil quality while ensuring stable oil temperature control. This significantly reduces wear on gearbox components and thus extends their service life. At the same time, the system ensures maintenance-friendly operation of wind turbine gearboxes, increases plant efficiency, and minimizes unplanned downtime.

Related products

- Oil filter modules

- Offline filter systems

- 2 and 3 stages filter element

Oil filtration in the azimuth drive

The precise alignment of the wind turbine nacelle via the azimuth drive is crucial for optimal energy generation and efficiency. Only with exact positioning can the turbine make the best possible use of the wind and achieve maximum performance. The hydraulic systems that control this drive are particularly sensitive to oil contamination, as impurities can impair function and lead to premature wear. Filtration Group offers filtration solutions specifically tailored to the demanding requirements of azimuth drives, ensuring the hydraulic oil remains clean. This increases operational reliability, extends the service life of components, and significantly reduces maintenance.

Related products

Our brands

A strong partner for wind energy

Filtration Group GmbH

As a global innovation leader in filtration solutions, Filtration Group ensures that wind turbines operate efficiently, safely, and reliably, even under the harshest conditions. With customized hydraulic, oil, and air filtration systems, Filtration Group protects critical components such as pitch and braking systems, gearboxes, and tower cooling systems from contamination and wear. In this way, the brand enhances the performance, availability, and sustainability of modern wind turbines – from onshore to offshore projects worldwide.

Visit the brand pageNews from the world of filtration

Learn about innovations, tips, and industry trends

Knowledge that moves you forward

Discover exciting insights, technical innovations, and practical solutions related to filtration in wind turbines. Our blog posts explain how Filtration Group's filtration systems sustainably improve the efficiency, lifespan, and reliability of pitch systems, braking systems, gearboxes, and tower air conditioning – for clean, safe, and high-performance wind energy today and tomorrow.

Product video

How filtration works for maximum performance in wind turbines

Downloads

All documents at a glance

FG Broschüre Windkraft.pdf

HerunterladenFG Broschure Wind Power.pdf

Download