FILTREC

FILTREC Hydraulic Filters - Quality that sets standards

Durability, reliability, and maximum filtration performance – that's what FILTREC hydraulic filters stand for. With decades of experience, in-house research and development, and state-of-the-art production in Italy, FILTREC offers innovative solutions for a wide range of applications. Whether replaceable filter elements, hydraulic oil filters, or process filters: FILTREC products impress with precision, sustainability, and an excellent price-performance ratio.

FILTREC Product Categories

Quality products in our shop.

Hydraulic Filters

FILTREC offers high-performance solutions for keeping hydraulic systems clean – from suction and line filters to return-line filters. All filters are tested according to strict ISO standards and achieve filtration levels down to <4.5µm (c) with ßx=1000.

The product range includes pressure filters (24 - 420 bar, flow rate up to 450 l/min), return-line filters (up to 1,200 l/min), suction filters (up to 600 l/min), mobile filtration units, and air/breather filters (up to 1,800 Nl/min).

Hydraulic Filter Elements

FILTREC offers a wide range of high-quality filter elements. All hydraulic filter elements are tested in our own laboratory according to the latest ISO standards and impress with the highest filtration levels down to <4.5µm (c) with ßx=1000.

Whether inline, return, coreless, anti-ESD, or spin-on filter elements, every product guarantees maximum compatibility, durability, and efficiency. Environmentally friendly materials, water-absorbing media, and specially configured filter solutions round out the range.

Alternative Filter Elements

FILTREC's product range includes high-quality alternative filter elements designed to fit a wide range of manufacturers, including ARGO HYTOS, CJC, Donaldson, Fairley Arlon, Faifiltri, Fleetguard, HYDAC, Internormen, Mann & Hummel, PALL, Parker, SOFIMA, and UCC.

All alternative filter elements meet or exceed the original performance, offer full dimensional compatibility, and are tested according to the latest ISO standards. With filtration levels down to <4.5µm (c) with ßx=1000, they reliably protect your hydraulic systems and ensure a long service life – whether inline, return-line, or spin-on filters.

Spare Parts

FILTREC offers a comprehensive range of hydraulic spare parts designed for maximum reliability and a long service life for your systems. From clogging indicators to seals, all parts are tested according to the highest ISO standards and guarantee a precise fit and optimal functionality.

With FILTREC spare parts, you ensure the trouble-free operation of your hydraulic systems and benefit from proven "Made in Italy" quality.

Who is FILTREC?

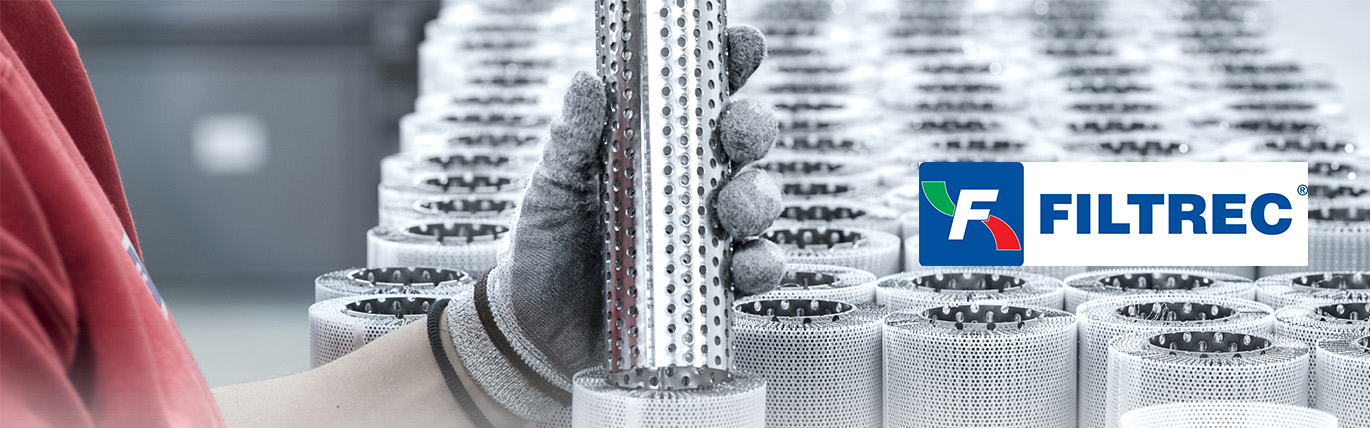

Made in Italy: FILTREC sets standards in filtration

FILTREC is a leading international manufacturer of hydraulic and process filters with headquarters and production facilities in Italy. Since its founding, the company has stood for technological innovation, the highest product quality, and close partnerships with its customers.

With modernly equipped factories, its own research laboratory, and a team of experienced specialists, FILTREC develops customized filter solutions that set standards worldwide. The company combines Italian engineering expertise with a clear focus on sustainability and future viability – from the selection of materials and energy-efficient production processes to recyclable filter elements.

Thanks to a global network of branches and partners, FILTREC is able to respond flexibly and reliably to the specific requirements of every market.

FILTREC in Italy thus stands for competence, reliability, and innovation "Made in Italy" – values that make the company a trusted partner in all matters of filtration.

Production at the highest level

Production at FILTREC in Italy combines state-of-the-art manufacturing technologies with decades of filtration expertise. The highly developed factories produce hydraulic and process filter systems that impress with their precision, reliability, and durability.

In-house machinery, automated production lines, and strict quality controls according to international ISO standards ensure that every product meets the highest customer requirements – from replaceable filter elements to customized complete systems. Particular attention is paid to the selection of high-quality materials, meticulous workmanship, and sustainable production processes.

Production is supported by the in-house research and development laboratory, which continuously tests and improves new materials and filter concepts. This results in filter systems "Made in Italy" that set standards worldwide and are reliably used in a wide variety of industries.